GO-ST d.o.o. is an established family-owned company with over 30 years of tradition, specializing in the production, sales, installation, and servicing of professional catering equipment. Based in Grosuplje, the company is renowned for its high-quality solutions for professional kitchens, combining its own production of stainless steel equipment with the representation of recognized brands. Their competitive advantage is based on comprehensive customer support – from initial design to final implementation and maintenance.

The Challenge

Despite delivering premium end products, the company faced backend challenges due to analog production management that could no longer keep up with growth and modern business needs. Before the implementation of the new system, the process was characterized by:

-

Manual Management and Paper Documentation: Digital work orders did not exist. Production was managed via Excel spreadsheets and printed technical sketches, with data added manually by hand.

-

Physical Document Circulation: Technical documentation physically moved between workstations in paper form, increasing the risk of information loss or the use of outdated versions.

-

Lack of Integration: The ERP system (SAOP) and CAD tools were not connected, requiring time-consuming manual data entry and duplication of work.

-

Difficult Planning: Work preparation, Bill of Materials (BOM) creation, and inventory management were lengthy processes based on static data, making optimal resource allocation difficult.

The goal was to digitize the entire process, eliminate paper-based operations, and introduce advanced planning capabilities.

Approach and Technology

We developed a comprehensive MES (Manufacturing Execution System), tailored to the specifics of bespoke catering equipment manufacturing, along with a separate web application for sales support.

The system was designed on a modern technology stack that ensures modularity and high performance:

MES System (Backend & Frontend):

-

User Interface: Vue.js, Nuxt.js, TypeScript (for responsiveness and clarity on workstations).

-

Backend System: Node.js, Nest.js, TypeScript.

-

Database: MySQL for structured data and MinIO for storing extensive technical documentation.

-

Integrations: Two-way connection with SAOP ERP and integration with Autodesk Inventor for automated BOM capture.

3D Sales Application:

-

Technology: Next.js, React.js, TypeScript.

Key Features

The solution covers the entire lifecycle of a production order:

-

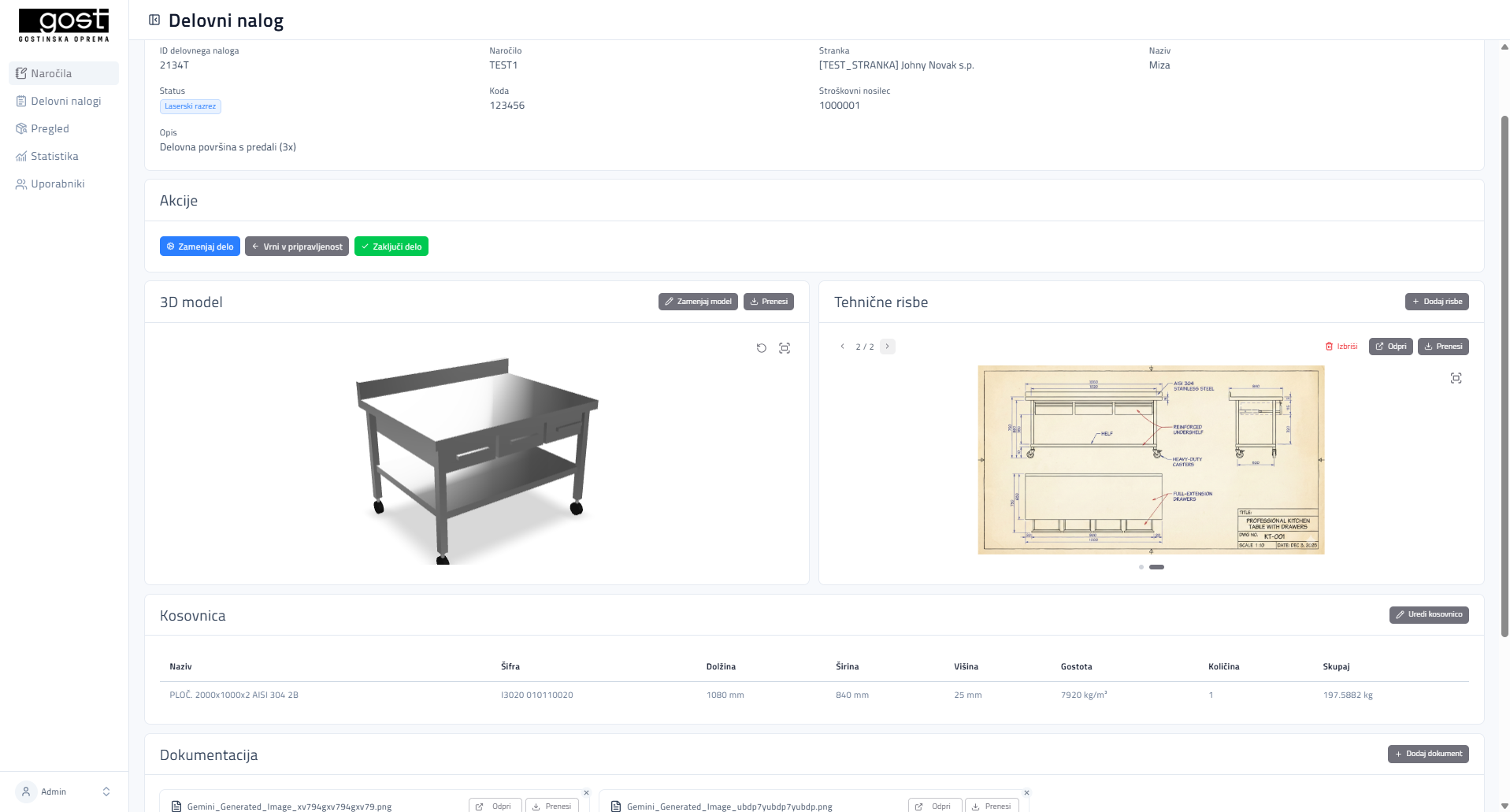

Smart Production Management: Complete digitization of work orders and real-time tracking of manufacturing status.

-

Digital Documentation: Workers at stations access current plans and documentation directly via tablets or computers, paper-free.

-

BOM Automation: Connection with the CAD tool (Autodesk Inventor) allows for automatic preparation and import of Bills of Materials directly into the system.

-

AI Optimization:

-

Production Planning: Machine learning algorithms assist in scheduling work orders for optimal capacity utilization.

-

Inventory Management: Advanced forecasting of material consumption and procurement optimization.

-

-

KPI Dashboard: A transparent dashboard for management featuring key performance indicators.

-

Customer Notifications: The system automatically generates notifications about order status for the end customer.

-

Interactive 3D Offers: Salespeople can send customers a link to an offer where they can view a 3D model of their future kitchen or element directly in their browser.

Architecture

The system architecture is designed as a hybrid to meet production security requirements and sales accessibility:

-

Internal Core: The MES system acts as a central hub orchestrating data between the ERP system (orders, warehouse data) and the engineering department (CAD plans).

-

Microservices and Containerization: The application runs in Docker containers, allowing for easy upgrades and maintenance of individual modules.

-

Separate Sales Interface: The 3D viewing application is architecturally separate and optimized for web traffic but draws model data from the central repository.

Infrastructure

Due to specific requirements for security and high-speed transfer of large files in production, we opted for a split approach:

-

On-Premise: The MES system is hosted on GO-ST's internal servers. This ensures lightning-fast loading of technical documentation on workstations and operation even in the event of an internet connection failure.

-

Cloud: The 3D offer application is hosted in the cloud, ensuring high availability for end customers anywhere and anytime, without burdening the company's internal network.